Landoll 7431 VT Plus User Manual

Browse online or download User Manual for Special machinery Landoll 7431 VT Plus. Landoll 7431 VT Plus User Manual

- Page / 98

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

- Model 7431 1

- Operator’s Manual 1

- Table of Contents 3

- 5 Troubleshooting Guide 4

- Introduction 5

- Understanding Safety 6

- Statements 6

- Standard Specifications 7

- STANDARD SPECIFICATIONS 10

- LANDOLL CORPORATION 10

- Assembly Instructions 25

- ASSEMBLY INSTRUCTIONS 26

- 7431 VT Plus Frame and Hitch 27

- Assembly 27

- Leveler Assembly 29

- Manual Leveler 31

- Hydraulic Leveler (Option) 33

- Center Frame Tires 37

- Disc Gangs 37

- Wing Frames 37

- 3-16 F-561-0113 Edition 40

- 3-18 F-561-0113 Edition 42

- 3-20 F-561-0113 Edition 44

- 3-22 F-561-0113 Edition 46

- 3-24 F-561-0113 Edition 48

- Hydraulic Installation 49

- 3-26 F-561-0113 Edition 50

- Light and SMV Bracket 51

- 3-28 F-561-0113 Edition 52

- LED Light and SMV Bracket 53

- 3-30 F-561-0113 Edition 54

- Conditioner Reel Installation 55

- 3-32 F-561-0113 Edition 56

- 3-34 F-561-0113 Edition 58

- 3-36 F-561-0113 Edition 60

- 7431 hyd reel assy op 61

- Reel Installation (Option) 62

- 3-40 F-561-0113 Edition 64

- Rear Tow Hitch Installation 65

- Rear Jack Installation 66

- Final Assembly 66

- Operation and Maintenance 69

- 7430 scraper adj 70

- Attaching to the Tractor 71

- Hydraulic Lift System 71

- 6230translock2 72

- Hydraulic Fold System 73

- 7431 installed locks 74

- 7431 stored locks 74

- General Operation 75

- Field Operation 75

- Leveling (Side to Side) 76

- OPERATION AND MAINTENANCE 77

- 7431levelmeas 77

- 7431wingliftadj 77

- 7431-20-wing-adj 77

- LEVELER HANDLE 78

- THIS LEVELER LINK IS 78

- NOT ADJUSTABLE. IT IS 78

- SET IN THE 3RD HOLE 78

- DOWN FROM THE TOP 78

- Hydraulic Leveler Adjustment 79

- Hitch Adjustment 80

- Scraper Adjustment 81

- Front Gauge Wheels 82

- Disc Blades 83

- DEPTH STOP TUBE 84

- DEPTH STOP 84

- DEPTH STOP HANDLE 84

- Wheel Bearing Maintenance 85

- Hydraulic Maintenance 85

- Transport 86

- Lubrication Maintenance 89

- Storage 90

- Chapter 5 93

- TROUBLESHOOTING GUIDE 94

Summary of Contents

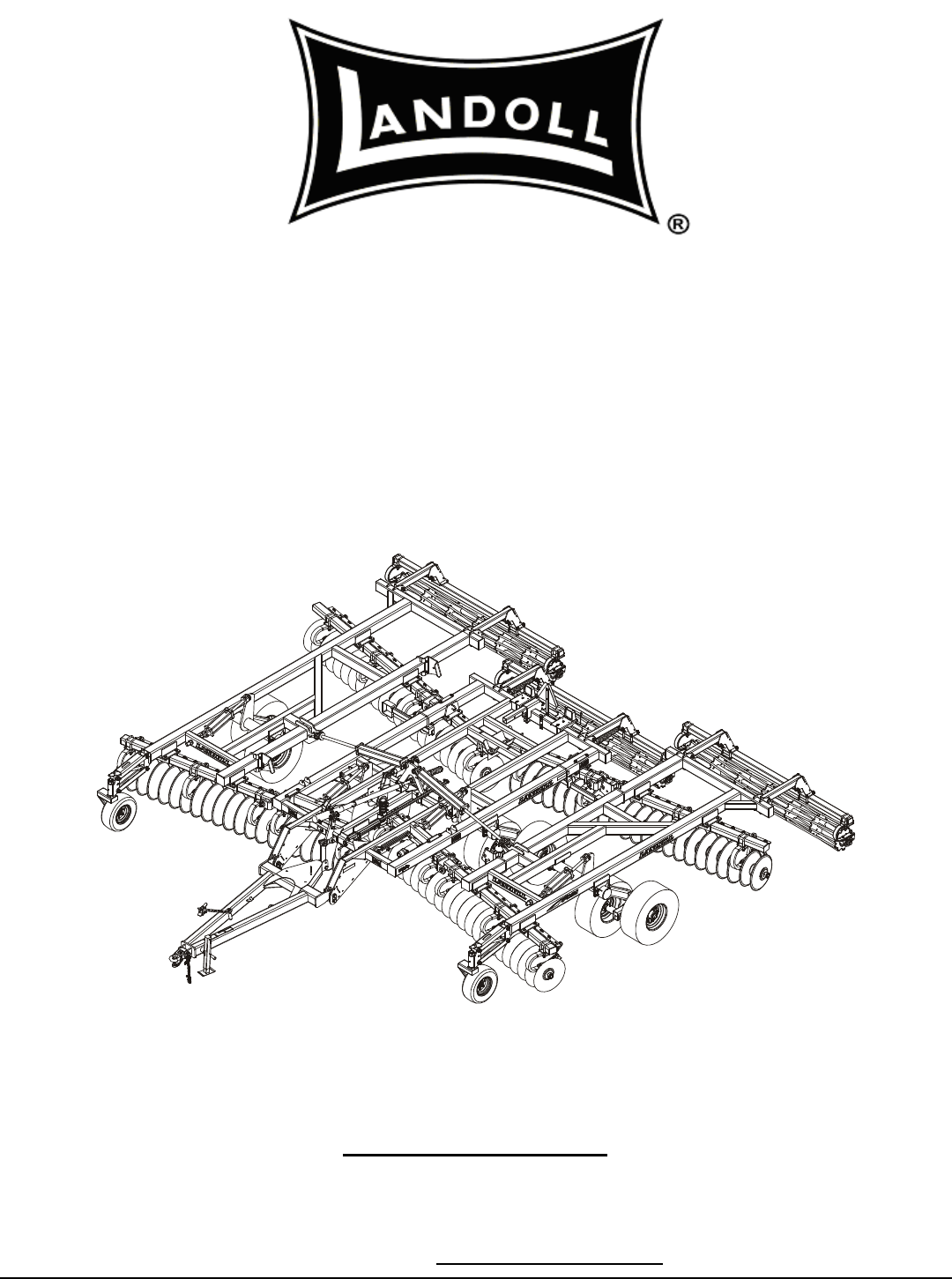

F-561-0113 01/2013LANDOLL CORPORATION1900 North StreetMarysville, Kansas 66508(785) 562-5381800-428-5655 ~ WWW.LANDOLL.COMModel 7431VT PlusOperator’s

2-4 F-561-0113 EditionSTANDARD SPECIFICATIONSTable 2-2: Hydraulic Fitting Torque SpecificationsLANDOLL CORPORATIONHYDRAULIC FITTING TORQUE SPECIFICATI

STANDARD SPECIFICATIONS2-5Figure 2-1: Wing Stabilizer and Light Bracket Placement (20' Model)(Left Half)9”97-3/4”26”24-1/2”114”7431-20 top p126-3

2-6 F-561-0113 EditionSTANDARD SPECIFICATIONSFigure 2-2: Wing Stabilizer and Light Bracket Placement (20' Model)(Right Half)8”133”43”7431-20 top

STANDARD SPECIFICATIONS2-7Figure 2-3: Wing Stabilizer and Light Bracket Placement (23' Model)(Left Half)9”97-3/4”28”24-1/2”114”7431-23 top p126-3

2-8 F-561-0113 EditionSTANDARD SPECIFICATIONSFigure 2-4: Wing Stabilizer and Light Bracket Placement (23' Model)(Right Half)8”133”43”7431-23 top

STANDARD SPECIFICATIONS2-9Figure 2-5: Wing Stabilizer and Light Bracket Placement (26' Model)(Left Half)7430-26 top p19”97-3/4”26-1/2”30”24-1/2”1

2-10 F-561-0113 EditionSTANDARD SPECIFICATIONSFigure 2-6: Wing Stabilizer and Light Bracket Placement (26' Model)(Right Half)7431-26 top p28”133”

STANDARD SPECIFICATIONS2-11Figure 2-7: Wing Stabilizer and Light Bracket Placement (29' Model)(Left Half)9”97-3/4”30”24-1/2”26-3/4”7430-29 top p1

2-12 F-561-0113 EditionSTANDARD SPECIFICATIONSFigure 2-8: Wing Stabilizer and Light Bracket Placement (29' Model)(Right Half)8”133”30”43”7430-29

STANDARD SPECIFICATIONS2-13Figure 2-9: Wing Stabilizer and Light Bracket Placement (33' Model)(Left Half) (Prior to July, 2012)7431-33 top p114-1

2-14 F-561-0113 EditionSTANDARD SPECIFICATIONSFigure 2-10: Wing Stabilizer and Light Bracket Placement (33' Model)(Right Half) (Prior to July, 20

STANDARD SPECIFICATIONS2-15Figure 2-11: Wing Stabilizer and Light Bracket Placement (33' Model)(Left Half) (After July, 2012)7431-33 top p1 after

2-16 F-561-0113 EditionSTANDARD SPECIFICATIONSFigure 2-12: Wing Stabilizer and Light Bracket Placement (33' Model)(Right Half) (After July, 2012)

STANDARD SPECIFICATIONS2-17Page Intentionally Blank

2-18 F-561-0113 EditionSTANDARD SPECIFICATIONS

3-1Chapter 3Assembly InstructionsIt is very important that your new 7431 VT Plus be properly assembled, adjusted and lubricated before use. Illustrati

3-2 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-1: Frame and Hitch Assembly Installationframe and hitch assyWING NUTHOSE HOLDERCLAMP3/8-16 HEX NUT

ASSEMBLY INSTRUCTIONS3-37431 VT Plus Frame and Hitch AssemblyIMPORTANTRead all safety precautions at the front of the section before attempting any of

3-4 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-2: Leveler Assembly Installation7431 leveler assembly8” LEVELER LINK1”N FLAT WASHER1 X 7-7/8LEVELE

ASSEMBLY INSTRUCTIONS3-5Leveler Assembly1. Install a hardened steel wear bushing in the leveler L link (See Figure 3-2.)2. Attach the leveler L link t

F-561-0113 Edition iTable of Contents1 IntroductionUnderstanding Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-3: Manual Leveler Installationmanual leveler assembly1/4 ZERK FITTINGLEVELER TUBE5/8-11 HEX LOCK N

ASSEMBLY INSTRUCTIONS3-7Manual Leveler1. Using the manual leveler, screw the leveler tube onto the leveler screw assembly (See Figure 3-3.) Initially

3-8 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-4: Hydraulic Leveler Installationhyd leveler assembly3-1/2 X 6CYLINDER1/2-13HEXLOCK NUT1/2-13 X 2H

ASSEMBLY INSTRUCTIONS3-9Hydraulic Leveler (Option)1. Thread a 1-1/2-6 hex nut onto the leveler screw assembly (See Figure 3-4.) Initially leave approx

3-10 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-6: Center Disc Gang Installation (20’, 23’, 26’, 29’)LEFT REAR CENTERFRAME DISC GANGCONNECTIONRIG

ASSEMBLY INSTRUCTIONS3-11Figure 3-7: Center Disc Gang Installation (33’)LEFT REAR CENTERFRAME DISC GANGCONNECTIONRIGHT REAR CENTERFRAME DISC GANGASSEM

3-12 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-8: Wing Frame Installation3/4-10 X 2 HEX HEADCAP SCREWRIGHT WING FRAMEFRONT GAUGEWHEEL ASSEMBLY1-

ASSEMBLY INSTRUCTIONS3-13Center Frame Tires1. Install the tire and wheel assemblies on the center section.2. On 20’, 23', and 26’ models, use 12.

3-14 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-9: Hydraulic Cylinder Fitting InstallationFOLDCYLINDERS90 FITTING W/ 1/16 RESTRICTOR(FACTORY INST

ASSEMBLY INSTRUCTIONS3-15Figure 3-10: Lift Hydraulic Installation (20’ and 23’ Models)lift hyd assy 23’ op(C)(A)(B)(E)(H)(F)(A)(B)(E)(F)(G)(H)(C)(D)FR

ii F-561-0113 EditionHydraulic Leveler Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-16 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-11: Fold Hydraulic Installation (20’ and 23’ Models)fold hyd assy 23’(D)(A)(B)(C)(E)(F)PLUG PORTS

ASSEMBLY INSTRUCTIONS3-17Figure 3-12: Lift Hydraulic Installation (26’ Model)lift hyd assy 26’ op3/8 X 112MASTER DECAL4 X 10 3/8 X 30 HOSE ASSEMBLY3

3-18 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-13: Fold Hydraulic Installation (26’ Model (Before 07/01/2012))fold hyd assy 26’ op5/16 X 2-1/2 S

ASSEMBLY INSTRUCTIONS3-19Figure 3-14: Lift Hydraulic Installation (29’ Model)lift hyd assy 29’ opPLUG PORTS H & O(A)(B)(C)(D)(I)(J)(K)(L)(M)(N)(O)

3-20 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-15: Fold Hydraulic Installation (26’ (After 07/01/2012) & 29’ Models)fold hyd assy 29’ opPLUG

ASSEMBLY INSTRUCTIONS3-21Figure 3-16: Lift Hydraulic Installation (33’ Model)lift hyd assy 33’ op3/8 X 136MASTER DECAL4 X 10 3/8 X 42HOSE ASSEMBLY3/8

3-22 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-17: Fold Hydraulic Installation (33’ Model)fold hyd assy 36’ op5/16 X 2-1/2 SPRINGSLOTTED PIN1-1/

ASSEMBLY INSTRUCTIONS3-23Figure 3-18: Bolt On Wing Fold Hydraulic Installation (Option) (7431-26’)7430-26 fold hyd assy option opPLUG PORTS H & O(

3-24 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-19: Bolt On Wing Fold Cylinder and Fold Mount Placement (7431-26)Figure 3-20: Hose Clamp Assembly

ASSEMBLY INSTRUCTIONS3-25Hydraulic InstallationNOTERefer to 3-9 for hydraulic cylinder fittings (factory installed and those installed during setup).R

1-1Chapter 1IntroductionThe Landoll Model 7431 VT Plus is a quality product designed to give years of trouble free performance. By following each sect

3-26 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-21: Light and SMV Bracket Installation (Prior to August, 2013)elect assyMAIN WARNINGLIGHT HARNESS

ASSEMBLY INSTRUCTIONS3-27Light and SMV Bracket Installation (Prior to August, 2013)1. Attach lights and mounting brackets to the center frames using u

3-28 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-22: LED Light and SMV Bracket Installation (After August, 2013)m177034 elect opNOTE: LED LIGHTS,

ASSEMBLY INSTRUCTIONS3-29Figure 3-23: LED Light and SMV Harness Wire Designations (After August, 2013)LED Light and SMV Bracket Installation (After Au

3-30 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-24: Conditioner Reel Installation7431 conditioner reel op1-8 X 6-1/2 HEX HEADCAP SCREW1-8 HEX NUT

ASSEMBLY INSTRUCTIONS3-31Conditioner Reel Installation1. Assemble 1 x 8 adjustment bolt through adjustment pin on frame, 1" lock washer, (2) 1-8

3-32 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-25: Finishing Reel Hydraulic Installation (7431-20)m172984 op(E-1)(F-1)(A)(B)(G)(H)(C)(D)FRONT OF

ASSEMBLY INSTRUCTIONS3-33Figure 3-26: Finishing Reel Hydraulic Installation (7431-23)m172985 op(E-1)(F-1)(A)(B)(G)(H)(C)(D)FRONT OFMACHINE(E-2)(F-2)45

3-34 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-27: Finishing Reel Hydraulic Installation (7431-26)m172986 op(E-1)(F-1)(A)(B)(G)(H)(C)(D)FRONT OF

ASSEMBLY INSTRUCTIONS3-35Figure 3-28: Finishing Reel Hydraulic Installation (7431-29)m172987 op(E-1)(F-1)(A)(B)(G)(H)(C)(D)FRONT OFMACHINE(E-2)(F-2)45

1-2 F-561-0113 EditionINTRODUCTIONUnderstanding Safety StatementsYou will find various types of safety information on the following pages and on the m

3-36 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-29: Finishing Reel Hydraulic Installation (7431-33)m172988 op(E-1)(F-1)(A)(B)(G)(H)(C)(D)FRONT OF

ASSEMBLY INSTRUCTIONS3-37Figure 3-30: Finishing Hydraulic Conditioner Reel Installation (Option)7431 hyd reel assy op1-1/2 BEARING FLANGE1-1/2 PIVOT B

3-38 F-561-0113 EditionASSEMBLY INSTRUCTIONSFinishing Hydraulic Conditioner Reel Installation (Option)NOTESRefer to Figure 3-25 for hydraulic diagram

ASSEMBLY INSTRUCTIONS3-39Figure 3-32: Finishing Hydraulic Conditioner Reel Hose and Clamp Installation (Option)DETAIL AHOSE CLAMPS ONDISC GANG BAR7431

3-40 F-561-0113 EditionASSEMBLY INSTRUCTIONSFigure 3-33: Rear Tow Hitch Installation (Option)7431 rear tow hitch inst3/4-10 X 5-1/2 HEXHEAD CAP SCREWA

ASSEMBLY INSTRUCTIONS3-41Rear Tow Hitch InstallationA rear tow hitch assembly is available for use on the rear of the VT Plus.1. Attach front clamp to

3-42 F-561-0113 EditionASSEMBLY INSTRUCTIONSRear Jack InstallationA rear jack assembly is available for use on the rear of the VT Plus.IMPORTANTThe re

ASSEMBLY INSTRUCTIONS3-43Notes:

3-44 F-561-0113 EditionASSEMBLY INSTRUCTIONS

4-1Chapter 4Operation and MaintenanceDANGERDANGERWARNINGWARNINGDANGERDANGERCAUTIONNever allow anyone to ride on the 7431 VT Plus at any time. A

2-1Chapter 2Standard Specifications7431 VT PlusModel No. 7431-20 7431-23 7431-26 7431-29 7431-33Working Width19’-10” 23’-2” 26’-3” 28’-11” 33’-2”Trans

4-2 F-561-0113 EditionOPERATION AND MAINTENANCETractor PreparationThe Landoll 7431 VT Plus is designed to be pulled by tractor equipped with a double

OPERATION AND MAINTENANCE4-3Attaching to the Tractor1. Align the tractor drawbar with the machine. Raise or lower the disc ring hitch, as needed, usin

4-4 F-561-0113 EditionOPERATION AND MAINTENANCE2. The hydraulic system is not filled with oil and should be purged of air before transporting and fiel

OPERATION AND MAINTENANCE4-5Hydraulic Fold System1. The VT Plus is equipped with a hydraulic fold system to raise and lower the wing frames for narrow

4-6 F-561-0113 EditionOPERATION AND MAINTENANCE5. To fold/unfold the VT Plus, find a level area large enough to accommodate the VT Plus when it is ful

OPERATION AND MAINTENANCE4-7General Operation1. The horsepower requirements are typically 8-10 horsepower per foot of cut. This will vary widely due t

4-8 F-561-0113 EditionOPERATION AND MAINTENANCELeveling (Side to Side)1. An adjustable radius rod connects the center frame lifts together to keep the

OPERATION AND MAINTENANCE4-93. After adjusting the cylinder rod or rods, the radius rod needs to be adjusted back to a neutral position. This is accom

4-10 F-561-0113 EditionOPERATION AND MAINTENANCELeveling (Front-to-Rear)1. The leveling feature on the VT Plus is used to keep the machine level when

OPERATION AND MAINTENANCE4-11Figure 4-14: Hydraulic Leveler AdjustmentHydraulic Leveler AdjustmentIf a unit is equipped with an optional hydraulic lev

2-2 F-561-0113 EditionSTANDARD SPECIFICATIONSWARNINGRECOMMENDED TORQUE SPECIFICATION FOR LUG BOLTS AND NUTSBOLT SIZE TORQUE (FT. LBS.)9/16-18 (Heavy

4-12 F-561-0113 EditionOPERATION AND MAINTENANCEHitch Adjustment1. It is important for the VT Plus to maintain a proper draft line with the tractor to

OPERATION AND MAINTENANCE4-13Scraper AdjustmentThe VT Plus is equipped with rigid scrapers at regular spools with dual scrapers at the disc bearings.F

4-14 F-561-0113 EditionOPERATION AND MAINTENANCEFront Gauge Wheels1. The VT Plus is equipped with castering gauge wheels at the outer front corners of

OPERATION AND MAINTENANCE4-15Disc Blades1. The 7431 VT Plus is equipped with 22" -6 ga. (.197"), 22" -4 ga. (.256), or 22" -4 ga.

4-16 F-561-0113 EditionOPERATION AND MAINTENANCEDepth Stop Adjustment (Manual)The operating depth of the VT Plus is controlled by a single-point depth

OPERATION AND MAINTENANCE4-17Wheel Bearing MaintenanceWheel bearing maintenance should be performed at the beginning of every season of use. Check the

4-18 F-561-0113 EditionOPERATION AND MAINTENANCETransport1. Check and follow all federal, state, and local requirements before transporting the VT Plu

OPERATION AND MAINTENANCE4-197. Check that tires are of proper size, load rating, and inflated to manufacture specifications before transporting. Chec

4-20 F-561-0113 EditionOPERATION AND MAINTENANCEFigure 4-22: Lubrication ScheduleTable 4-1: Lubrication TableLUBRICATION TABLEITEM DESCRIPTION NO. OF

OPERATION AND MAINTENANCE4-21Lubrication Maintenance1. Table 4-1 specifies the number and the period of lubrication points on the 7431 VT Plus. Proper

STANDARD SPECIFICATIONS2-3Table 2-1: General Torque SpecificationsLANDOLL CORPORATIONGENERAL TORQUE SPECIFICATIONS (REV. 4/97)THIS CHART PROVIDES TIGH

4-22 F-561-0113 EditionOPERATION AND MAINTENANCEStorage 1. The service life of the VT Plus will be extended by proper off-season storage practices. Pr

OPERATION AND MAINTENANCE4-23Notes

4-24 F-561-0113 EditionOPERATION AND MAINTENANCEPage Intentionally Blank

5-1Chapter 5Troubleshooting GuideThe Troubleshooting Guide, shown below, is included to help you quickly locate problems that can happen using your 74

5-2 F-561-0113 EditionTROUBLESHOOTING GUIDEWHEEL BEARING FAILURE Seals not installed correctly Install seals with the lips pointing outward away from

TROUBLESHOOTING GUIDE5-3Notes:

5-4 F-561-0113 EditionTROUBLESHOOTING GUIDEPage Intentionally Blank

Equipment from Landoll Corporation is built to exacting standards ensured by ISO 9001:2008 registration at all Landoll manufacturing facilities.Model

(96 pages)

(96 pages)

Comments to this Manuals